For over 30 years since establishment, Hanwha Chemical R&D Center has been committed to the development of cutting-edge technology and has led the advancement of chemistry in Korea with an aim to create a more prosperous future for humanity. While focusing on developing eco-friendly and value-added products in the existing polyolefin and chemical businesses, we also seek out and conduct research into next-generation technologies and materials to drive our future growth and adopt innovative measures to cut costs and improve processes to further strengthen our business competitiveness.

Hanwha Chemical R&D Center strives to become a global industry leader by developing technologies centered on respect for humanity.

- Securing future growth engines Based on an R&D strategy aligned with the enterprise-wide roadmap, we develop original technologies and new products that will facilitate the commercialization of new businesses that will lead the industry.

- Strengthening existing competencies In order to secure leading position in existing businesses and expand value-added specialty product portfolio, our research projects focus on advancing conventional processes, improving product quality, and reducing cost.

- Creating a pool of best experts We ensure a creative research environment and run diverse programs to nurture talent in an aim to pursue advanced research and foster highly qualified experts.

- Building a global R&D network We focus on securing original and core technologies for the global market by conducting joint R&D products with promising global enterprises and leading organizations all over the world.

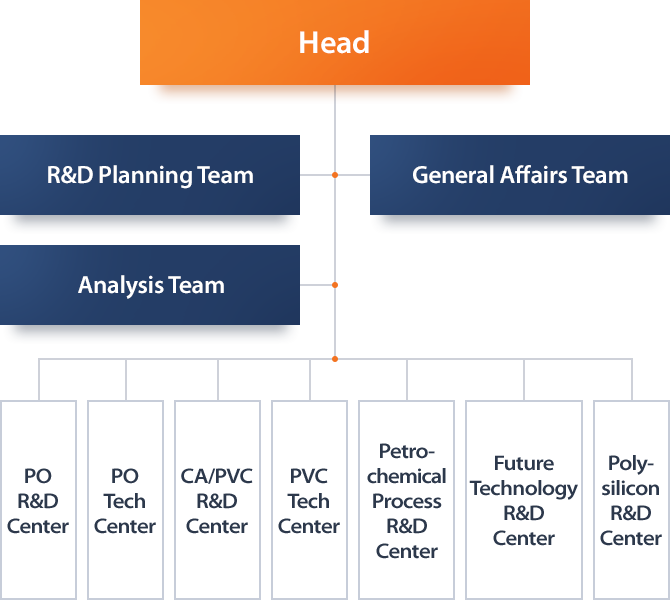

R&D Organization

- Head

- R&D Planning Team

- General Affairs Team

- Analysis Team

- Polyolefin R&D Center

- PO Tech Center

- CA/PVC R&D Center

- PVC Tech Center

- Petrochemical Process R&D Center

- Future Technology R&D Center

- Polysilicon R&D Center

R&D History

- 1979 Established Daedeok R&D Center

- 1982 Succeeded in developing LDPE for wire & cable

- 1995 Succeeded in developing LLDPE for insulation

- 1996 Succeeded in independent development of high-content EVA for shoe soles

- 2002 Succeeded in proprietary development of ASR

- 2003 Secured original technology for ultra-high-content EVA

- 2008 Succeeded in developing DOTP plasticizer

- 2011 Best Government R&D Project: LLDPE for cable with outstanding processability and mechanical property

- 2012 Commercialized HDPE for film & injection molding

Succeeded in developing eco-friendly plasticizer - 2016 Succeeded in Korea's first domestic production of CPVC

Key Research Areas

-

- PVC / Specialty PVC

- Main areas of research: PVC, Paste, CP/TP, CPVC

- Our research on multiple grades of PVC formulation and production process will further strengthen existing business competitiveness. In order to expand our portfolio and strengthen profitability, we also carry out researches on copolymer, terpolymer and CPVC, developing highly functional specialty products.

-

- Eco-friendly Plasticizer

- Main areas of research: Eco-DEHCH

- In line with the eco-friendly trend in the market, we conduct research on general-purpose eco-friendly plasticizers and plasticizers with specialized functions. Eco-DEHCH, in particular, is an eco-friendly plasticizer whose stability and processability have been improved remarkably. Developed by our proprietary technology, it has already been commercially produced and are sold on the market.

-

- Catalyst

- Main areas of research: Metallocene Catalyst, Ziegler-Natta Catalyst, Petrochemical Catalyst

- Our research on developing metallocene and Ziegler-Natta catalysts aims at securing original technologies and developing high-value-added specialty PE products. We also conduct petrochemical catalyst research to diversify our product portfolio and secure further competitiveness.

-

- Olefin Polymer

- Main areas of research: Ethylene Homo/Co polymer(LD, LLD, HD, m-LLD, EVA, W&C etc.)

- Our research on diverse olefin products (EVA, LDPE, LLD/HDPE, metallocene PE, W&C compound) aims at satisfying customer needs by developing specialty products with improved durability and processability.

-

- Functional Polymer

- Main areas of research: DCPD petroleum resin, high-performance adhesive resin, alkali soluble resin

- We are developing polymers that take on an adhesive quality when added to products and create materials used in the production of diverse functional adhesives, tapes, hygiene products, food packaging, printing ink, surface protection coating, paint, etc. Main products under development are functional polymers, such as hydrogenated petroleum resin, which is a material for adhesives used in hygiene products and food packaging, and eco-friendly alkali soluble resin.

-

- Petrochemical Process

- Main areas of research: Manufacturing processes for petroleum resin, eco-friendly plasticizer, isocyanate, and intermediates for new products, energy-saving separation process, PE polymerization process

- Research on process development is indispensable for the commercialization of new processes. The project involves the development of optimized process design and energy-saving reaction/separation process technologies by concept design of new processes, selection of economical reaction route, and computer demonstration, focusing on enhancing the economics of commercial process. In particular, we are building our competence in independent commercial process design/construction and innovating manufacturing process technology by focusing on high-value-added intermediates, improvement of reaction/polymerization process, and unit improvement/stability enhancement of commercial processes.

R&D Track Record

-

CPVC

- Outline

- CPVC resin manufacturing technology and process development through base PVC morphology control technology and optimized chlorination reaction

- Special Traits

- Improved in heat and chemical resistance compared to PVC and easier to use than steel pipes, it is applied to sprinklers, industrial pipes, and hot water pipes

- Milestones

-

- Korea's first CPVC commercialization (2017)

- Received 2016 NET certification

-

Eco-DEHCH

- Outline

- Highly functional non-phthalate eco-friendly plasticizer

- Special Traits

-

- Superb properties as plasticizer, e.g. low viscosity and translocation property

- Perfect non-phthalate eco-friendly plasticizer

- Milestones

-

- Received 2014 NET certification

- Completed construction of commercial plant through proprietary technology (2017)

- Gained FDA approval for products containing Eco-DEHCH

- REACH implemented in 2013

-

Ultra-high-voltage Cable (XLPE)

- Outline

- Crosslinked PE for cable insulation

- Special Traits

- Clean Technology' lowered contamination, in order to improve insulating and electrical properties

- Milestones

-

- Replaced import-dependent insulation material with domestic product

- Multiple domestic and international certificates of cables applied XLPE

- Selected world-class product of Korea from 2008

-

ASR

- Outline

-

- Alkali water soluble resin and emulsion for print ink and paper coating

- Development of water soluble resin and emulsion with outstanding chemical resistance and durability, used For wood and metal coating

- Special Traits

-

- An eco-friendly water soluble resin that can be used for pigment dispersion and emulsion production.

- Wood coating emulsion with a 3-layered structure that gives it a special, balanced property

- Milestones

-

- Developed proprietary technology and expanded Thai plant

- Completed product line-up with soluble resin for graphic art and emulsion

- Received Best Environmental Technology Award (2001)

- Received 2004 NET certification

- Received Presidential Commendation for New Technology Commercialization

-

High-content EVA

- Outline

- Korea's only petrochemical manufacturer to succeed in commercializing 40% EVA produced through autoclave technology

- Special Traits

- High transparency, elasticity, and adhesiveness that provide high suitability for adhesive and shoe sole application

- Milestones

- Used in production for HMA(Glue), Running Shoes, and Ink Application

-

DOTP

- Outline

- Non-phthalate plasticizer with excellent stability and economics

- Special Traits

-

- Eco-friendly plasticizer with superb transparency, heat-resistance, and Stability

- Applied with eco-friendly production process generating less waste water

- Milestones

-

- Korea's first commercial production

- Process design and plant construction done through independent technology

-

DCPD hydrogenated petroleum

- Outline

- Non-toxic, high-quality hydrogenated petroleum resin

- Special Traits

-

- Highly transparent, colorless, and odorless polymer resin

- Non-toxic and improved quality through hydrogenation; to be used in producing high-quality hot-melt adhesives for hygiene, food, and medical use

- Milestones

-

- Independent development of high-temperature polymerization and high-pressure hydrogenation processes

- Plant engineering and construction underway using proprietary technology

- Developed high-transparent, color-and odorless product

-

Metallocene hybrid catalyst

- Outline

- Development of Metallocene Hybrid Catalyst for gas-phase process which can be used for the production of MD/HDPE having excellent mechanical properties and processability

- Special Traits

- It can produce MD/HD having excellent Long-term hydrostatic strength, environmental stress crack resistance and processability

- Milestones

-

- Acquired quality certification of PE-RT TYPE Ⅱ from EXOVA in 2017

- Acquired New Excellent Technology(NET) certification from Korean Government in 2016

-

PE-RT

- Outline

- Development of PE-RT(Polyethylene of Raised Temperature Resistance) TYPE Ⅰ/Ⅱ for the application of eco-friendly hot-water pipe having excellent long-term hydrostatic strength

- Special Traits

- With the help of molecular structure designing technology, such as hybrid catalyst technology and short chain branching distribution control, it provides excellent long-term hydrostatic strength and processability

- Milestones

- Acquired quality certification of PE-RT TYPE Ⅰ/Ⅱ from EXOVA in 2016 and 2017, respectively.